6063

The most popular

of the aluminium extrusion alloys

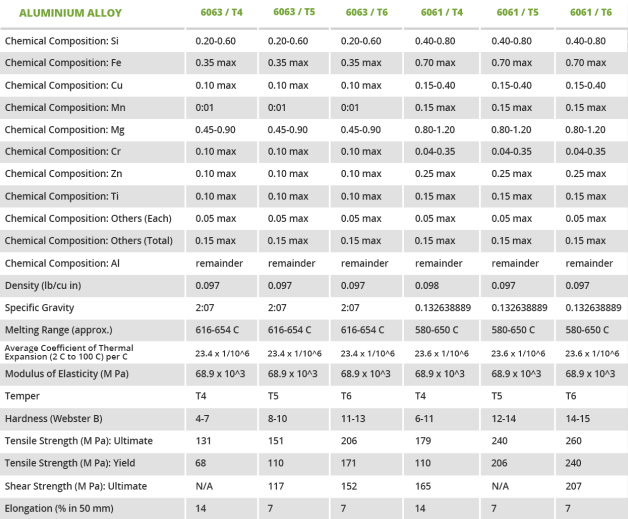

Not only it is the most cost-effective, this alloy produces a good surface finish, is corrosion resistant and can be heat-treated for strength. This alloy is used in fabricated parts such as: windproof windows, windproof doors, storefronts and commercial buildings. In other words, it is primarily used in non-structural applications, but occasionally used in structural applications.

Application: Architectural, Electronic Parts, Industrial and Engineering Products, General Purpose, Household, Furniture, Automotive.

6061

Known for its structural

strength and hardness

Common grades of 6061 is 6061-0, 6061-T4, and 6061-T6. “T6” indicates that the material has been solution heat-treated and artificially aged. Highly resistant to corrosion, does well with applied coatings and good weldability.

Application: Aircraft Fittings, Camera Lens Mounts, Couplings, Marines Fittings and Hardware, Electrical Fittings and Connectors, Decorative or Misc. Hardware, Hinge Pins, Magneto Parts, Brake Pistons, Hydraulic Pistons, Appliance Fittings, Valves and Valve Parts, Bike Frames.

6005/6005A

Medium strength with excellent

corrosion resistance

Has properties similar to those of alloys 6106 and 6082 and can sometimes be used interchangeably with them, but 6005/6005A has better extrusion characteristics and a better mill surface finish. However, it is hard to create intricate, thin-walled shapes in this alloy.

Application: Tubing for Furniture, Ladders, Railway and Bus Profile Structures, Solar Panel Mounting, Pylons, Platforms and Pipelines, Products where greater strength is needed than given by 6060 and 6063.

Product Parameters

Aluminium alloy series

ID

ID CN

CN