Aluminum Billet

We mainly specialize in 6063, 6005, and 6061 alloy aluminum Billet. Every aluminum Billet undergoes spectral analyzer composition testing before extrusion, ensuring that the alloy indicators meet the required standards with high precision.

Dies

We have a professional technical team that designs and manufactures Dies according to customers product drawings and process requirements. Meanwhile, we conduct regular maintenance and upkeep on the Dies to ensure the final products meet the required standards and tolerance specifications.

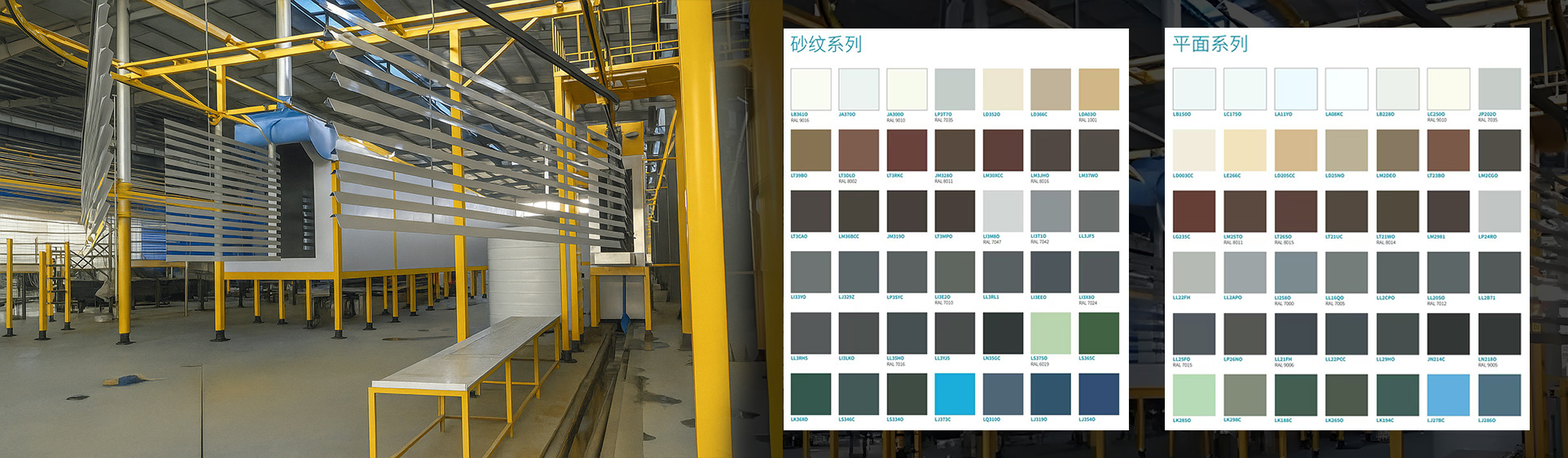

Aluminum Profile Extruder

Heated and softened aluminum rods are fed into the extrusion cylinder. The main cylinder drives the aluminum billets at high pressure to flow through the opening of the mold cavity, where the billets conform to the cavity and are shaped into aluminum profiles with corresponding cross-sections. Our extrusion production line can manufacture profiles with maximum sizes of 4 inches, 5 inches, and 6 inches.

Aluminum Profile Aging Furnace

As the core equipment for the aging process, the aluminum profile aging furnace drives the diffusion of elements such as Mg (magnesium) and Si (silicon) in the supersaturated solid solution after solution treatment through precise temperature and time control. This forms a dispersed nano-scale strengthening phase, realizing the "aging strengthening" effect. It can double the strength of aluminum profiles in the O-temper state, while significantly improving their hardness and mechanical stability.

ID

ID CN

CN