Process Flow and Technical Requirements

In addition to custom aluminium, our company also offers fabrication

and assembling services for your needs, including:

Step 1: Dies

Step 2: Extrusion

Step 3: Aging

Step 4: Sandblasting

Step 5: Anodizing

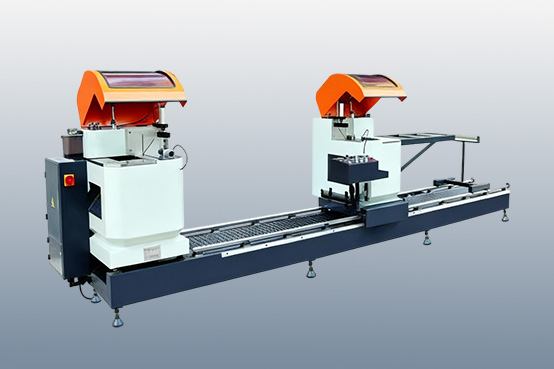

Step 6: Cutting

Step 7: Punching

Step 8: Packing

ID

ID CN

CN